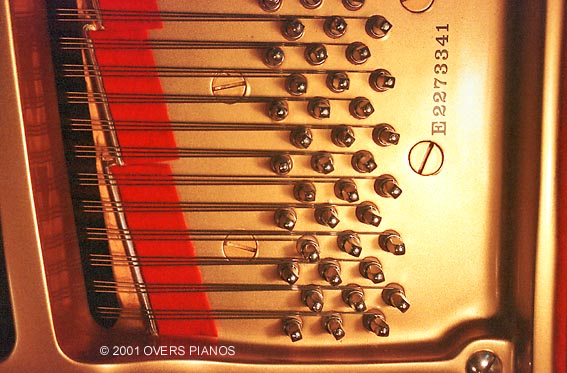

YAMAHA G2 DETUNED FRONT DUPLEX SYSTEM

This is the first Overs Pianos rebuild where the cast in bars were deliberately detuned

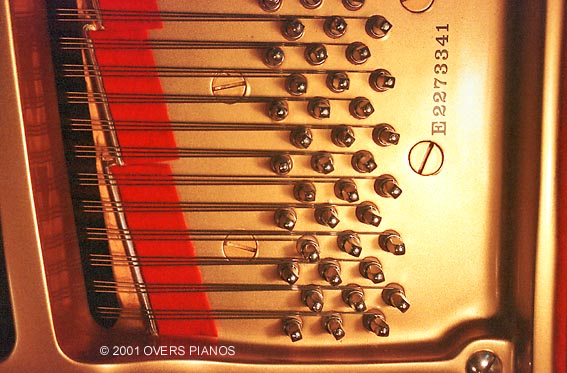

YAMAHA G2 DETUNED FRONT DUPLEX SYSTEM

This is the first Overs Pianos rebuild where the cast in bars were deliberately detuned

Ron Overs has been reshaping duplex and Capo bars since 1989, and hardening them since 1994. The recently rebuilt G2 Yamaha, shown above, was a late '70s piano which had the typical wide front duplex bars of the period. Interestingly, careful measurement of the speaking lengths and front duplex lengths revealed that considerable care was taken by Yamaha during production to set the front duplex lengths to a specific fraction of the speaking lengths (each duplex length was set to a specific ratio, relative to the speaking length). Duplex lengths measured by the author were within 0.5 mm of the actual length intended (measurements on the duplex bars were taken from the centre of the relatively wide apex of the bar - these early Yamaha grand pianos produced considerable string noise as they aged). Since the lengths were all slightly on the short side of 'in-tune', a decision was taken to further shorten the duplexes to detune them (shortening is also a preferred option over lengthening the duplexes since shorter lengths are typically less noisy than the longer examples).In Overs rebuilt grand pianos, cushion felt is used as an understring felt adjacent to the front duplex bars. The typically used firm understring felt is thought to contribute to string rendering problems with older instruments, especially if they have been exposed to moisture and humidity. The understring felt function, in an Overs manufactured/rebuilt piano is therefore limited to damping the dead string lengths only, and is not intended to be used as a string bearing surface.

Reffering to the image of the rebuilt G2 shown above, if you check the lower of the front duplex bars shown in the image, you will notice (looking at the top end of the bar where the profile can be seen) that the duplex bar is now leaning quite noticeably towards the capo bar. When die grinding to reduce the bar's width and height, the bar width was reduced by removing material from the pin block side of the bar only (previously bars were reshaped by removing material equally from both sides of the bar). This effectively moved the bar apexes back towards the capo bar by slightly more than 1 mm, shortening the front duplex lengths. You will also notice that the font duplex apex radius is quite small, between 0.5 to 0.75 mm radius. A slightly larger radius is used for the capo bar, since it will subject the wire to greater fatigue and deformity than the duplex terminations. After hardening, the bars are polished to a smooth and uniform rounded surface. The bars are masked off prior to applying the gilding and clear coat. Ron Overs insists that the termination surfaces should be free of high hysteresis material such as lacquers and other finishing materials. The string approach angles from the duplex to the capo bar, relative to the angle of the speaking length, is set to slightly less than 15 degrees. In order to limit string breakage and wire deformation at the termination points, control of the string approach angle is critical when the bars are hardened and of a small radius. There are further design considerations to allow for when the front duplexes are set. Additional information will be provided in this space following the exhibit of the Overs-Steinbach 225 at Reno NV this coming July.

TO RETURN TO OVERS' MAIN BROWSER WINDOW, PLEASE CLOSE THIS WINDOW AT THE TOP-LEFT CLOSE BOX

First published 16 March, 2001

Last modified; 25 September 2001

Copyright © 2001, Overs Pianos.